The Fast, strong, easy way to join wood - Drill. Drive. Done!

How do pocket holes work?

Seven Simple Joints You Need to Know

Find the Right Pocket-Hole Jig

Kreg® Pocket-Hole Jig K4

The Kreg Pocket-Hole Jig K4 is the top choice for DIYers and anyone new to pocket-hole joinery. The K4 helps finish the job quicker and with less effort.

Kreg® Pocket-Hole Jig 520PRO

The Kreg 520PRO is the most versatile pocket hole jig for woodworking and DIY projects. Features VersaGrip™ intuitive clamping and a 360°-rotating handle.

Kreg® Pocket-Hole Jig 720PRO

The Pocket-Hole Jig 720PRO is the most advanced jig yet from Kreg® - designed for efficient woodworking and DIY project building.

Pocket-Hole Jig Accessories and Components

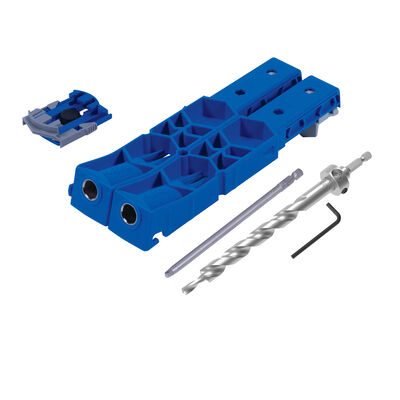

Kreg® Easy-Set Drill Bit with Stop Collar & Gauge/Hex Wrench

Add a second bit to your Kreg 300-Series Pocket-Hole Jig, or update any Kreg Jig to make working with 1/2", 3/4", and 1 1/2" materials even easier.

Kreg Micro-Pocket™ Drill Guide Kit 730

Use your 700-Series Pocket-Hole Jig to create 33% smaller pocket holes — great for small projects, ½" material, and narrow stock.

Custom Plug Cutter Drill Guide Kit

Use your 700-Series Pocket-Hole Jig to create custom pocket-hole plugs that blend into your project perfectly.

Screws Matter

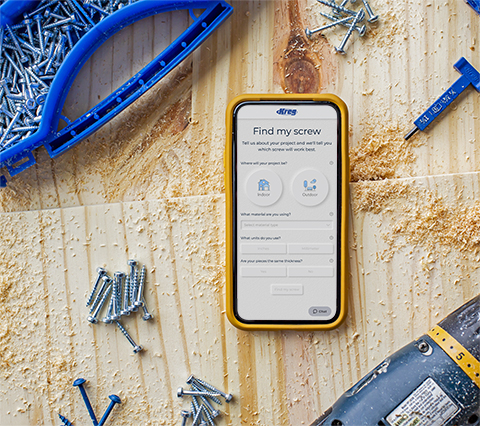

Find the right pocket-hole screw

Pocket-Hole Screws & Plugs

Stainless Steel Pocket-Hole Screws

Kreg Stainless Screws are specially designed for maritime applications, excessive exposure to water, and other exceedingly corrosive environments, such as ACQ-t...

Zinc Pocket-Hole Screws

Kreg Zinc Pocket-Hole Screws are the top choice for indoor wood projects. Available in a variety of sizes, thread options, head styles, and quantities.

Blue-Kote™ Pocket-Hole Screws

Blue-Kote Screws feature three anti-corrosion layers, making them the perfect choice for a wide variety of indoor and outdoor projects. Blue-Kote Screws provi...

Commercial Pocket-Hole Machines

General Joinery

MortiseMate™ Loose Tenon Jig

The MortiseMate™ Loose Tenon Jig allows you to create loose tenon joints with ease. Create professional-quality hidden joints with just a drill - no router needed.

90° Pocket-Hole Driver

Turn any drill into a 90° driver with this Kreg right angle drill adapter. Allows you to drive screws in places that you couldn’t normally reach with your drill.

Drilling Guide

The Kreg portable Drill Guide Jig makes it easy to create perfectly straight holes without a drill press. You can get precisely positioned holes with just a hand drill.

Start here with our best-selling pocket-hole jigs

Get Inspired

Kreg joinery in your shop and on the go

Pocket Holes 101

What is a pocket hole?

A pocket hole is an angled hole drilled into a piece of wood to create a strong, hidden joint when paired with a specialized screw. Pocket hole joinery is commonly used in woodworking and furniture building and allows for quick assembly without visible fasteners on the surface. The angled design increases holding power, ensuring a secure connection between boards while keeping the screw head concealed for a clean, professional finish.

Learn more in this article: How Pocket Holes Work - A Visual Guide.

What is the purpose of pocket holes?

Pocket-hole joinery is an incredibly fast, strong, and simple way of joining wood. It essentially involves drilling a hole at an angle into one workpiece, and then joining it to a second workpiece with self-tapping screws.

What is the advantage of pocket hole joints?

While it may seem simple, the technique is revolutionary because of how easy it is. When you're done assembling, there's no need to leave your joint clamped up for hours, glue is completely optional, and there are no frustrating alignment problems to deal with. Our jigs make it so simple that you can do it in a few easy steps - drill, drive, and you're done!

When to use pocket holes

Pocket-hole joinery is perfect for a wide variety of applications. From face-frame to panel joints, edge banding to complex curves, new builds, renovations, and repairs, pocket-hole joinery can do it all. Whatever your next project, a Kreg Pocket-Hole Jig can help you build it faster, easier, stronger, and with more confidence than ever before!

How to drill pocket holes

Kreg Pocket-Hole Jigs make it extremely easy to create pocket holes. As you drill, the stepped drill bit enters the wood at a 15° angle. That’s what makes the distinctive oval shape. The pocket-hole jig ensures this angle is consistent, and that the bit is held steady as you work — making the process of drilling an angled hole fast, simple, and efficient.

Check out our article on How to Use a Kreg Pocket Hole Jig

What angle are pocket holes drilled at?

Pocket holes are typically drilled at a 15-degree angle using a jig to ensure accuracy and consistency. This angle allows the screw to pass through the edge of one board and into the face or end grain of another, creating a tight and secure joint. The precise angle helps maximize holding strength while minimizing the risk of splitting the wood, making pocket hole joinery a reliable choice for various woodworking projects.

How strong are pocket holes?

As you drive a pocket-hole screw into your material, the pocket and pilot hole guide the screw precisely, while the screw’s self-tapping tip drills its own hole into the mating piece. That means you don’t have to drill into both pieces, and you’ll get great holding power without splitting or stripping the wood.

As you tighten the screw, it pulls the joint tightly together. The process is simple, but there are several things going on that make it possible. For starters, the upper part of the screw doesn’t have threads. That lets it turn easily inside the pilot hole instead of driving your two pieces of material apart.

Second, the flat underside of the screw mates perfectly with the ledge at the base of the pocket. This way, the head pulls the joint tightly together to create a super-strong, lasting joint.

What are the types of pocket hole joints?

Pocket-hole joinery is versatile and can be used to create edge joints, butt joints, mitered joints, edge banding joints, box joints, T joints, and offset edge joints.

Can you make pocket holes on plywood?

Absolutely. Plywood is a very common material for wood projects, and as such is a great application for pocket-hole joinery.

Can you make pocket holes on 2x4s?

Yes, you can use pocket holes on 2x4s, and it's a popular technique for building sturdy furniture, frames, and other woodworking projects. When working with standard 2x4 lumber (which actually measures 1.5 inches thick), you'll typically set your pocket hole jig for 1.5-inch material and use 2.5-inch pocket hole screws for a strong joint. This method allows for easy and durable construction, especially when assembling frames, tabletops, or shop furniture.

Can you make pocket holes on MDF?

Yes, medium-density fiberboard (MDF) is suitable for pocket-hole joinery. It does tend to be more prone to tearing and chipping along the edges, so a little extra care and Kreg pocket-hole screws can make a big difference in your results.

Get the answers to all your pocket hole questions here: Answers to Common Pocket-Hole Questions