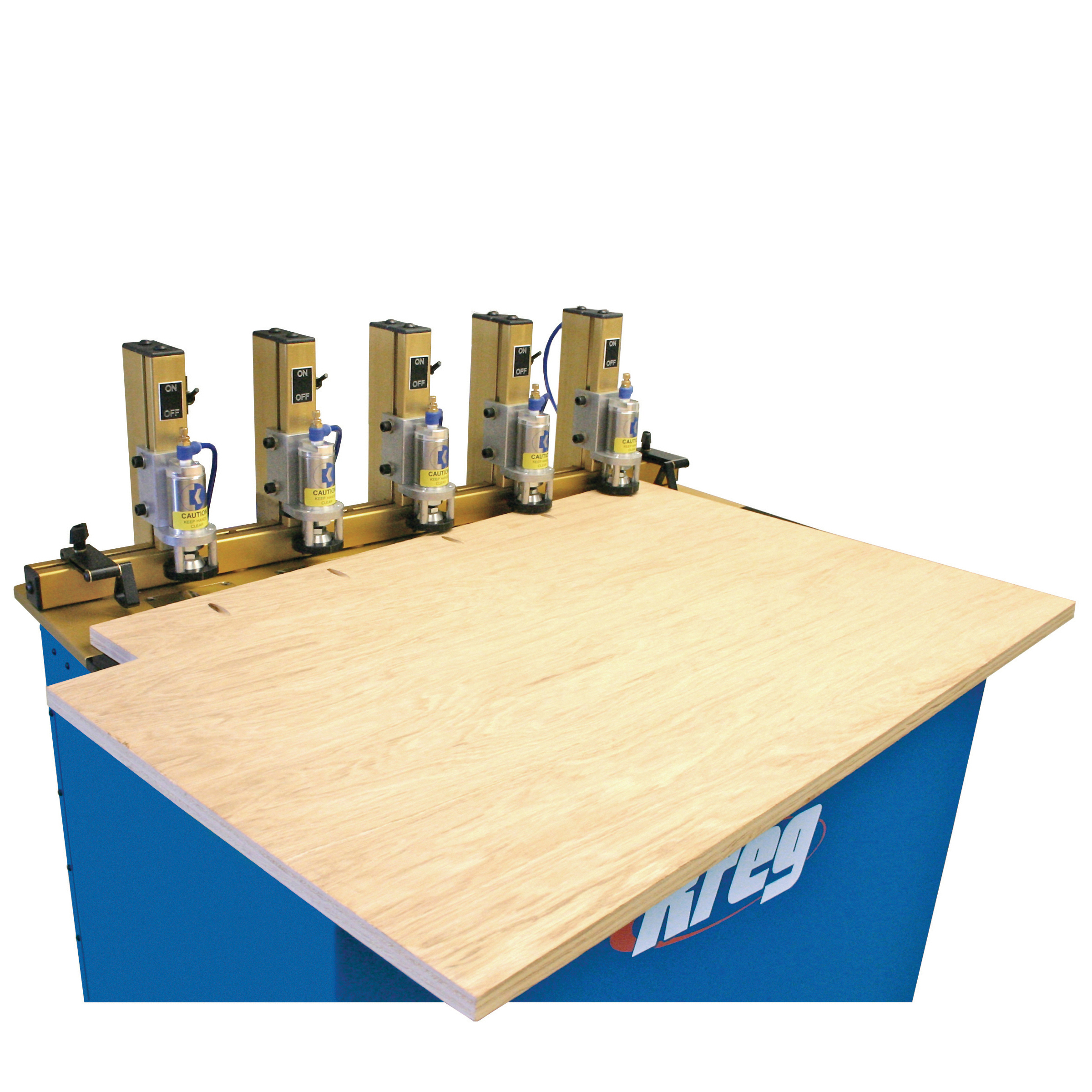

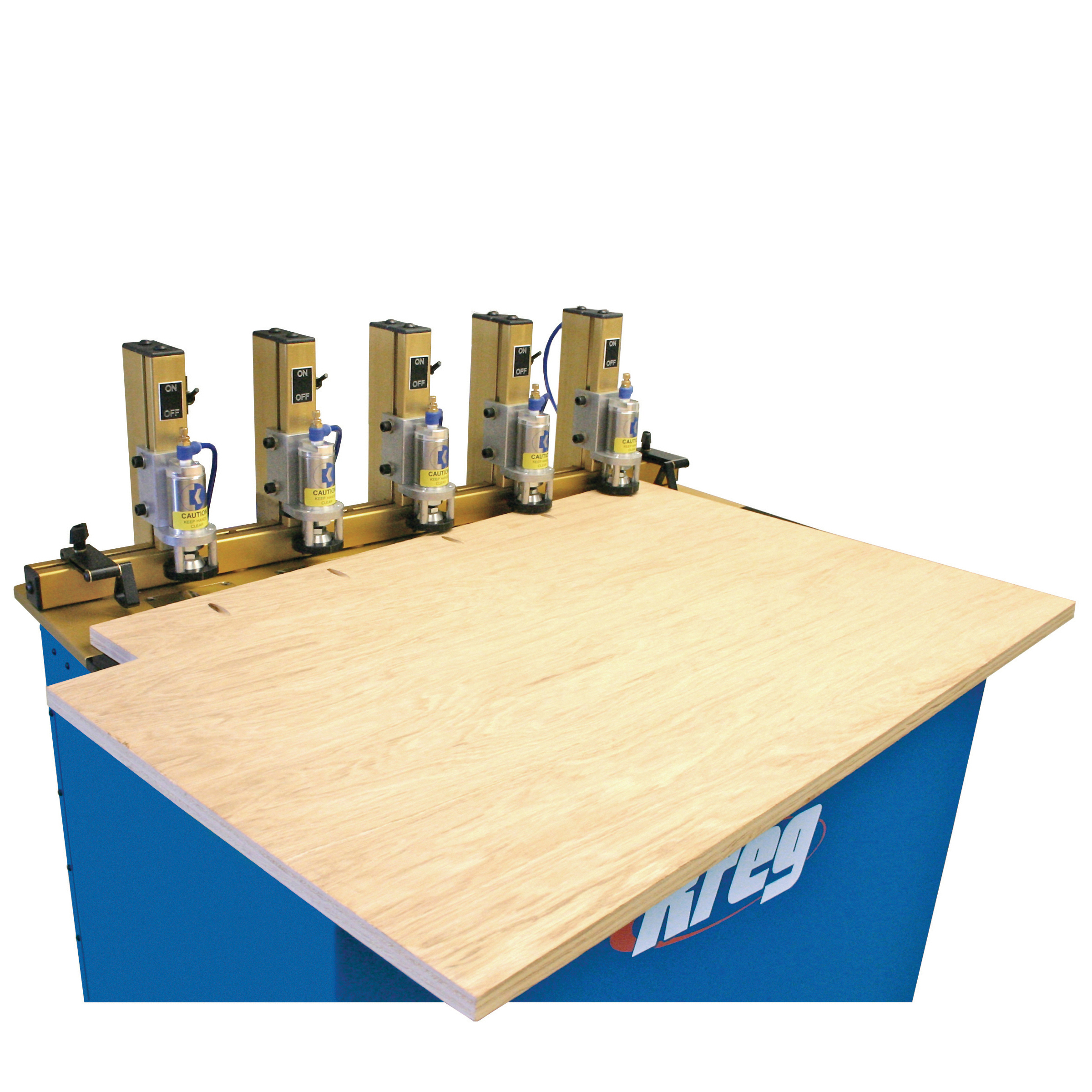

Panel-Boring Pocket Hole-Machine

Availability:

-

Call (800) 447-8638 to order. Current lead time is 21 days.

$13,999.99

- Highlights

- Five individually-actuated motors

- Five clamping cylinders

- Five durable drill spindles

- Entirely pneumatic design

- Hardened-steel drill guides to maximize drill bit life

- One-touch, foot pedal operation

- Swing Stops for optimized material positioning

- Dust collection chutes for efficient chip removal

- Pre-filter and automatic lubricator

Show More