The best wood for woodworking depends on specific projects and personal preferences – popular choices include hardwoods (oak, maple, cherry, and walnut) which are known for their durability and attractive grain patterns while softwoods (pine and cedar) are also commonly used for their affordability and ease of workability.

Ultimately, the best wood for woodworking is one that suits the project’s design, function, and desired aesthetics.

What sizes of boards can I buy?

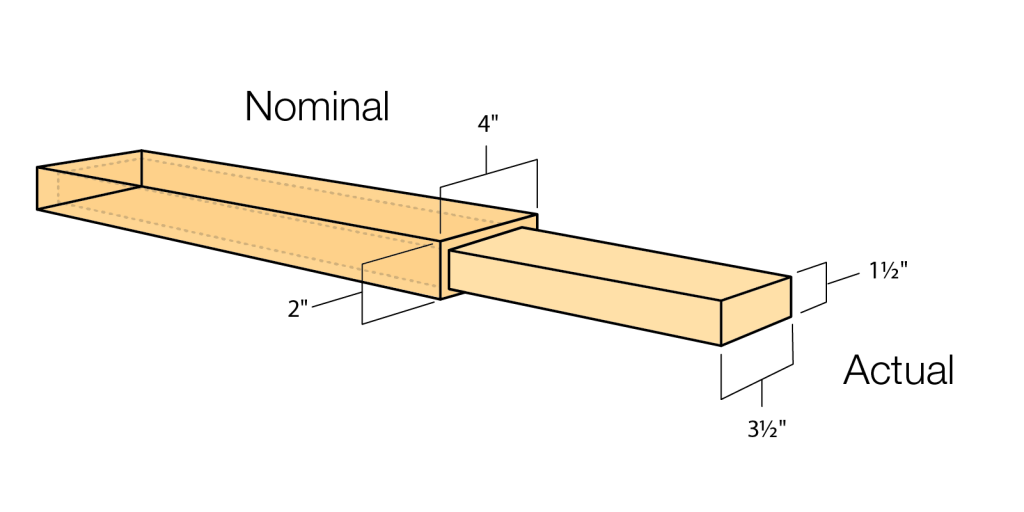

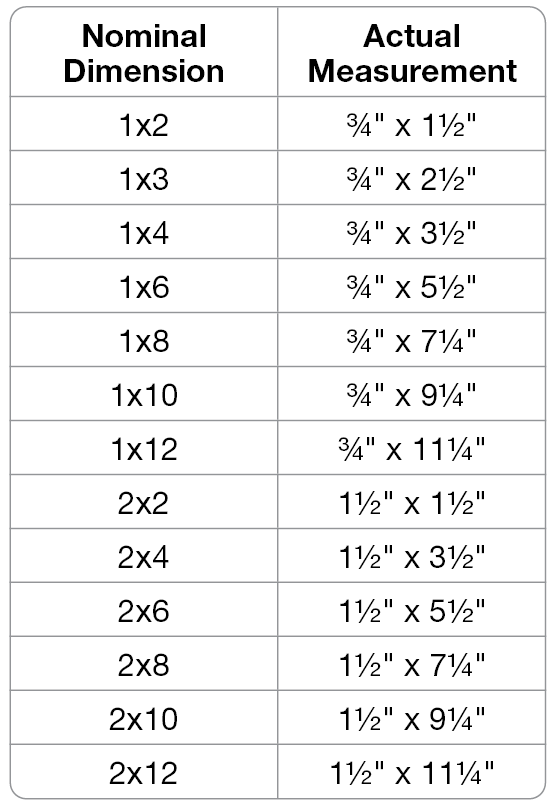

Lumber sold in a hardware store is all milled to standard thicknesses and widths. It’s commonly referred to as “1-by” or “2-by” for the thickness in inches, followed by the width in inches. So, you’ll hear lumber referred to as 1×6 (one-by-six), 2×4 (two-by-four), etc.

This can be confusing because those numbers don’t describe the true dimensions of the boards. 1×6 or 2×4 refers to the “nominal” thickness and width, which are greater than the “actual” thickness and width. The chart below shows the difference between nominal and actual sizes of common boards.

Here’s why that’s important for your projects:

- If you’re using a project plan, the materials list might say you need a 1×4 board (the nominal size), but the dimensions in the plan will show ¾” x 3 ½” (the actual size).

- If you’re drawing up your own project, be sure to use the actual dimensions. If you accidentally design your project using the nominal dimensions, it may not come together as you had planned.

What is the most recommended wood to use for woodworking?

The most recommended wood for woodworking often depends on several factors. However, some woods are commonly recommended for their versatility and suitability across a range of projects – pine, oak, maple, and poplar.

Home centers have several aisles filled with stacks of wall studs and other “2-by” boards up to 12″ wide. These boards are made for building homes and other structures. Since they’re usually hidden inside walls or under floors, construction boards don’t have to be pretty. They’re rated for strength and size — not for appearance.

Usually made from pine, or one of several similar species grouped as “whitewood,” 2-by dimensional boards can still be useful for DIY projects. They’re readily available, relatively inexpensive, and easy to work with.

The key to success with construction lumber is taking extra time to sort through the stacks and find the best-looking boards with the fewest defects. (More on common wood defects later.)

Pine and whitewood construction lumber

- Common Sizes: 2×2, 2×3, 2×4, 2×6, 2×8, 2×10, 2×12

- Softwood/Hardwood: Softwood

- Color: Light off-white to yellow

- Appearance: Semi-smooth surfaces, rounded edges, has knots and imperfections, may have gouges, grading stamps

- Common DIY Uses: Structures, farmhouse- and rustic-style furniture, storage & utility projects

- Workability: Easy to cut, drill, and glue; holds coarse-thread screws and nails

- Cost: $

Appearance boards

In a separate aisle from construction lumber, you’ll find better-quality boards referred to as “appearance boards.” As the name implies, these boards are made to have a much better appearance. You’ll usually find them standing vertically (rather than stacked like construction lumber) to help prevent damage.

Appearance boards aren’t meant for building structures. They’re great for things like interior trim and cabinets, as well as DIY and woodworking projects. Because of this, appearance boards have smooth surfaces and crisp edges. Home centers offer appearance boards in several typical softwood and hardwood species.

Softwoods used to be most commonly used for utility projects and DIY storage. But as farmhouse and rustic styles have become popular, softwoods are also used for building furniture and other woodworking projects. Though there are many kinds of softwoods, pine or whitewood are the most common in hardware stores.

If you want to create higher-end furniture or built-ins, you may want to build using hardwood. Though not all hardwoods are “hard,” they are generally denser and more durable than softwoods. Oak, poplar, and maple are common among home-center hardwoods. Some stores offer others such as aspen, cherry, or walnut.

Common pine and whitewood

For rustic furniture or utility projects, the classic “knotty pine” look remains popular. It’s also an economical choice because these are usually the lowest-priced appearance boards. Depending on where you shop, these boards may be pine or just “whitewood.” That means they could be pine, spruce, fir, or one of several similar species.

- Common Sizes: 1×2, 1×3, 1×4, 1×6, 1×8, 1×10, 1×12

- Softwood/Hardwood: Softwood

- Color: Off-white to light tan

- Appearance: Smooth surfaces, square edges, has knots and imperfections, may have gouges

- Common DIY Uses: Farmhouse- and rustic-style furniture, storage & utility projects

- Workability: Easy to cut, drill, and glue; holds coarse-thread screws or nails

- Cost: $

Premium pine

Home centers also carry a higher grade of pine, which is usually labeled Select, Premium, or Clear. This pine is free from knots and other internal imperfections, so it’s great for creating a higher-end look at a cost slightly lower than hardwoods. Clear pine is much more expensive than common pine, often costing three times as much or more.

- Common Sizes: 1×2, 1×3, 1×4, 1×6, 1×8, 1×10, 1×12

- Softwood/Hardwood: Softwood

- Color: Medium to dark tan

- Appearance: Smooth surfaces, square edges, pronounced grain pattern

- Common DIY Uses: Furniture, shelving, tables, built-ins (especially painted)

- Workability: Easy to cut, drill, and glue; holds coarse-thread screws or nails

- Cost: $$$

Poplar

- Common Sizes: 1×2, 1×3, 1×4, 1×6, 1×8, 1×10, 1×12

- Softwood/Hardwood: Hardwood

- Color: White with areas of yellow, gray, and green

- Appearance: Smooth surfaces, square edges, subtle grain pattern, may have large areas that are darker toned

- Common DIY Uses: Cabinets, built-ins, painted furniture, shelving

- Workability: Relatively easy to cut, holds coarse-thread screws well but may require pilot holes to prevent splitting, glues well

- Cost: $$$$

Oak

- Common Sizes: 1×2, 1×3, 1×4, 1×6, 1×8, 1×10, 1×12

- Softwood/Hardwood: Hardwood

- Color: Light to medium brown

- Appearance: Smooth surfaces, square edges, pronounced, attractive grain, often with an arched shape on the board faces

- Common DIY Uses: Traditional furniture, trim and millwork, cabinets, bookcases, built-ins

- Workability: Slightly difficult to cut, holds fine-thread screws well but may require pilot holes to prevent splitting, glues well

- Cost: $$$$$

Maple

- Common Sizes: 1×2, 1×3, 1×4, 1×6, 1×8

- Softwood/Hardwood: Hardwood

- Color: Off-white to very light tan

- Appearance: Smooth surfaces, square edges, subtle grain with light contrast

- Common DIY Uses: Mid-century furniture, cabinets, dining tables

- Workability: Moderately difficult to cut, holds fine-thread screws well but may require pilot holes to prevent splitting

- Cost: $$$$$

While these are some of the most recommended woods for woodworking, there are many other species available, each with its own unique characteristics and suitability for different applications. The best wood for a particular project depends on factors such as the desired appearance, durability, workability, and budget constraints. It’s essential to consider these factors carefully when selecting wood for woodworking projects.

What is the most common wood used in woodworking?

The most common wood used in woodworking is pine. Pine is widely available, relatively affordable, and easy to work with, making it a popular choice among woodworkers of all skill levels.

Pine is a softwood with a light color and straight grain, making it suitable for a variety of woodworking projects, including furniture, cabinetry, trim work, and DIY projects. It’s often used for interior applications where appearance and durability are important but where cost considerations also play a role.

In addition to pine, other softwoods such as cedar and fir are also commonly used in North American woodworking, particularly for outdoor projects like decks, fences, and outdoor furniture. These softwoods offer natural resistance to decay and insects, making them well-suited for exterior applications.

While hardwoods like oak, maple, cherry, and walnut are also popular choices for woodworking projects, pine remains the most common wood used due to its availability, affordability, and versatility across a wide range of applications.

Which wood is highest quality?

The quality of wood depends on various factors, including species, grade, and how it’s milled and seasoned. Generally, hardwoods like mahogany, cherry, and walnut are considered high-quality due to their density, stability, and attractive grain patterns.

Mahogany

Mahogany is prized for its rich color, attractive grain patterns, and durability. It is commonly used for fine furniture making, cabinetry, and decorative woodworking projects.

Cherry

Cherry features a warm, reddish-brown hue that darkens with age and exposure to light. It has a smooth, fine grain and is often used for high-end furniture, cabinets, and interior trim work.

Walnut

Walnut is known for its deep, chocolate brown color and striking grain patterns. It is highly valued for its beauty and workability, making it a popular choice for furniture, flooring, and decorative accents.

Maple

Maple is prized for its light color, smooth texture, and uniform grain patterns. It is exceptionally durable and takes finishes well, making it suitable for a wide range of woodworking projects, including furniture, cabinets, and cutting boards.

Oak

Oak is renowned for its strength, durability, and distinctive grain patterns. It comes in two main varieties: red oak, which has a warm, reddish hue, and white oak, which has a pale, golden tone. Oak is commonly used for furniture, flooring, cabinetry, and architectural millwork.

These hardwoods are highly regarded for their beauty, strength, and workability, making them top choices for discerning woodworkers seeking the highest quality materials for their projects. Ultimately, the best wood for woodworking depends on the specific requirements of the project and the preferences of the woodworker.

How do I choose wood for woodworking?

Choosing the right wood for your woodworking project is a crucial decision that can significantly impact the outcome. Some of the key factors to consider are the type of project, budget, wood species, wood appearance, and workability.

-

Project Requirements

Begin by assessing the specific requirements of your project. Consider factors such as the intended use of the finished piece, the desired aesthetic qualities, and any functional considerations.

-

Wood Species

Familiarize yourself with different wood species and their characteristics. Hardwoods like oak, maple, cherry, and walnut are prized for their durability, strength, and attractive grain patterns, making them ideal for furniture making, cabinetry, and decorative woodworking projects. Softwoods like pine and cedar are often used for structural applications and outdoor projects due to their affordability and ease of workability.

-

Appearance and Grain

Pay attention to the appearance and grain patterns of the wood. Consider whether you prefer a light or dark wood, grain pattern, and any natural imperfections that add character to the piece.

-

Workability

Evaluate the workability of the wood, including its hardness, stability, and ease of machining. Some woods are easier to work with than others, especially for beginners or those using hand tools.

-

Budget Considerations

Determine your budget for the project and select wood that fits within your financial constraints. Keep in mind that certain wood species may be more expensive or harder to source than others.

-

Finish and Treatment

Think about how you plan to finish or treat the wood. Some woods take stains, paints, and finishes better than others, so choose a wood that complements your desired finishing techniques and aesthetics.

-

Availability

Consider the availability of the wood in your region. While some wood species are readily available at local lumberyards or specialty suppliers, others may require special ordering or sourcing from distant locations.

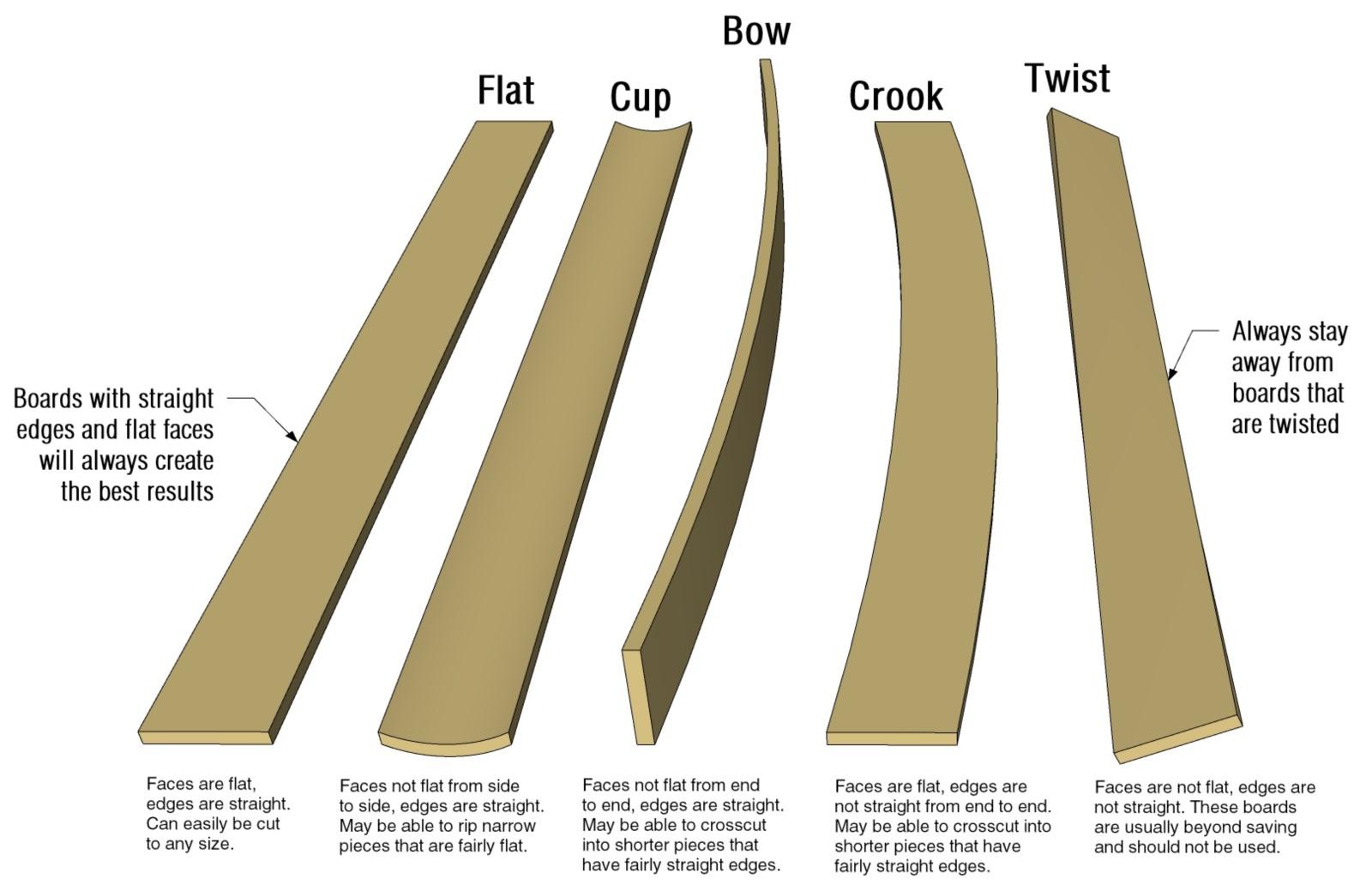

How do I choose the best lumber?

Take your time looking over the available boards (ideally, you want every board to be flat and straight) and check for common defects such as warping, cupping and twisting.

Here are some common problems associated with lumber:

Warped Boards

Warping occurs when boards develop twists, bows, cups, or crooks along their length. Warped boards can be challenging to work with and may result in gaps, uneven surfaces, or structural instability in your project.

Cupped Boards

Cupped boards have developed a concave or convex curvature across their width. This curvature resembles a cup shape, with the edges of the board raised or lowered relative to the center. Cupped boards may not lay flat when placed on a surface, making them difficult to join or plane evenly.

Twisted Boards

Twisted boards have developed a rotational twist along their length. These boards can be challenging to work with as they may not lay flat when placed on a surface, making it difficult to achieve tight and flush joints during assembly.

To mitigate these potential issues, carefully inspect lumber before purchasing or using it in your project. Choose boards with straight grain, minimal defects, and uniform moisture content whenever possible. Proper storage, acclimation, and handling techniques can also help minimize the risk of wood movement and other issues during woodworking projects.